|

CAP CODER NEWSLETTER - JULY 2017

Dear [FirstName1,fallback=Customer],

Welcome to our latest newsletter. In these newsletters, we will update you on our own news but will also inform and react to innovations in the packaging and manufacturing world. We will also feature helpful and entertaining articles including client case studies, useful advice in our Hints & Tips sections, and will set the occasional fun competitions for exciting prizes.

This month, we launch our new Mini-mono machine, we announce new updated versions of both our Rise and Fall and our Pick and Place Torque Heads, and introduce a new torque control element to be offered as an optional extra on most of Cap Coder's range of machines.

If there's any subject you would like us to discuss in these newsletters, please get in touch.

Ross Prior

Managing Director

T: 01865 891466

E: sales@capcoder.com

W: www.capcoder.com

ANNOUNCING CAP CODER'S NEW MINI-MONO CAPPING MACHINE

|

We are delighted to announce the launch of our new Mini-mono capping machine. The new Mini-mono has been nearly two years in the making. After consultation with our existing and prospective customers, we developed the Mini-mono as a cost-effective and space saving alternative to our popular CC1160, Cap Coder's flagship capping and filling machine.

We are delighted to announce the launch of our new Mini-mono capping machine. The new Mini-mono has been nearly two years in the making. After consultation with our existing and prospective customers, we developed the Mini-mono as a cost-effective and space saving alternative to our popular CC1160, Cap Coder's flagship capping and filling machine.

The Mini-mono has a smaller footprint, making it ideal for smaller rooms or areas with restricted space. It is adaptable and can be configured to suit many applications, including various combinations for filling, plugging and screw capping and is designed to work with a wide variety of caps from press-on caps, ROPP (roll-on-pilfer-proof) caps and crimp seal caps, to name but a few.

The Mini-mono can be configured to suit every budget from a fully automated solution, integrated into your production line, or can be used as a semi-automatic machine, where the operator manually applies the plugs, caps, and the seals for example.

The fully automated version can be supplied complete with bowl feeders for plugs and caps, and small bottles where suitable. Alternatively, bottles can be placed on a conveyor for feeding them into the machine and can also be used for handling the finished product to feed them to the next process.

Visit our Mini-mono page

If we can help you with bespoke or standard capping solutions, please contact Ross and his team on 01865 891466 or email: sales@capcoder.com

| |

| |

COST EFFECTIVE QUALITY CONTROL

|

In many applications, the ability to know and prove that a cap has been properly fitted AND tightened correctly to a precise measurement of torque is becoming more important. Quality control systems demand proof of performance and consistency and recording of this data onto a computer hard drive is especially useful.

In many applications, the ability to know and prove that a cap has been properly fitted AND tightened correctly to a precise measurement of torque is becoming more important. Quality control systems demand proof of performance and consistency and recording of this data onto a computer hard drive is especially useful.

The current method of achieving these results uses our torque transducer which can be fitted as an option to the torque head. This powerful sensor measures the applied torque every single time, is extremely accurate and also records this data for every cap.

For many applications this level of sophistication actually offers more than is required so Cap Coder have developed a more cost effective alternative. We have a developed an Intelligent Torque Head using a Schneider servo motor with its controls linked to the HMI (Human Machine Interface) on the main machine.

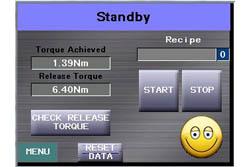

The torque limit and tolerance required by the motor to apply to the cap can be set in the HMI. This applied torque is then measured, visually displayed, and this data is logged on the hard disk.

The capping head also has the ability to untighten a cap, display and record the torque required by the motor, and then re-tighten the cap to the desired limit.

This can be achieved manually by pressing a programmable button on the HMI and can be set up to perform the test at required intervals or at random.

Although this method will not deliver as accurate and precise measurements as our transducer technique, it will suffice in most cases as it can be used to check that a consistent torque has been applied, and record the data. This feature will be available on most of our machines in the future, starting with the C570 model and then rolled out onto our other machines over the following months.

For Cost Effective Quality Control, please contact Ross and his team on 01865 891466 or email: sales@capcoder.com

| |

|

ABOUT CAP CODER

|

Cap Coder is a family-run UK engineering company specialising in the design and manufacture of both standard and bespoke bottling, capping & coding machines.

Established in 1976 and based near Oxford, Cap Coder offers practical and innovative solutions for all volume filling and capping requirements.

Cap Coder is a family-run UK engineering company specialising in the design and manufacture of both standard and bespoke bottling, capping & coding machines.

Established in 1976 and based near Oxford, Cap Coder offers practical and innovative solutions for all volume filling and capping requirements.

For over 40 years, we have continued to design, manufacture, supply and maintain bespoke machines and technical solutions to national and international clients in the pharmaceutical, chemical, complimentary medicine, cosmetic, toiletries, food and beverage, and e-cigarettes sectors.

We also design, build, develop and maintain Torque Heads for automatically applying caps or tightening caps placed onto containers. Everything we produce is manufactured to ISO 9001-2008 build standard, CE marked and supplied complete with a Certificate of Conformity or a Certificate of Incorporation as appropriate.

If you have any questions about filling, bottling, capping, coding, or any bespoke solutions for your production line, please contact Ross and his team on 01865 891466 or email: sales@capcoder.com

| |

|

|